Heavy duty CONSTRUCTION mesh welding machine

Production from pre-cut rebar - type Ribwel

The machine works with pre-straightened, cut to length, line and cross wires (or, cross wire off coil). For the greatest flexibility, line wires are, usually managed manually. To make production faster, line can be advanced by automatic line wire feeding trolley.

Feeding system will be going back during the welding procedure, to be re-filled, by the operator! That would virtually double the production speed!

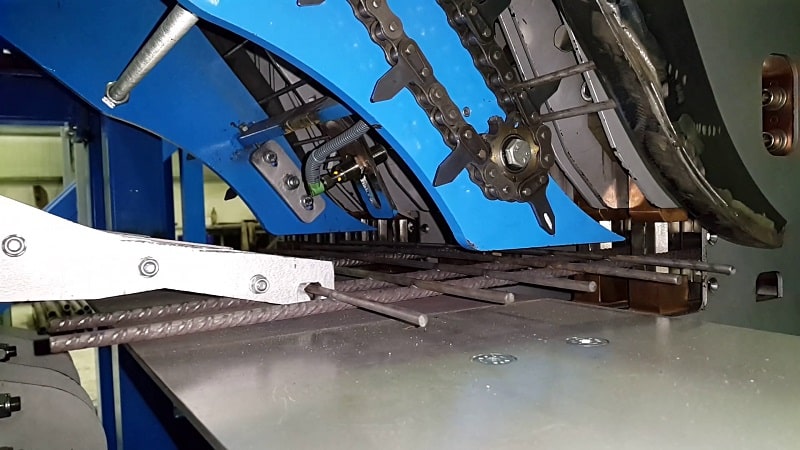

Cross wire is fed from PRE-CUT (or, off coil from payoffs) by cross wire automatic feeding system, into the Welding Unit,

A high precision servo carriage/car advances the mesh through the welding procedure.

The appropriate receiving table with rollers will accept the ready mesh panels.

Receiving – stacking unit could be completely automatic and hydraulically operated (going slowly down), receiving the ready panel and stacking the panels into a package.

Exclusive Features:

- From semi-auto to fully automatic

- High capacity HEAVY DUTY rebar mesh production

- UP and DOWN cross wire shooting to avoid overturning

- TAILOR-MADE – MANY LEVELS of upgrades

- SUPREME FLEXIBILITY in the production regime

Featured Performance Options:

- Wire thickness from 3mm to 20mm

- Optionally cross wire from coil

- Up to 4000mm wide

- Custom made extras, fully upgradable

Ready bundled mesh can be removed by crane!

Optionally, any length of motorized conveyor could be provided for easy and quick package moving to the desired position, in the production facility.

Due to the up/down cross wire shooting system, no turnover for mesh stacking is necessary!

This production line is almost completely automated, fully electronically controlled and easily managed by 2 operators!