STEEL GRATING PRODUCTION MACHINES

We have most innovative solution for the grating production.

Our Gradil line is specially designed to exploit in full the huge power transformers installed needed for grating welding (2400kVA)!

So, in addition to standard 1 m grating and 2 meter light grating panels for fencing, the same machine can make 2D (double cross) heavyweight 8-6-8mm security panels as well as all other standard and 2D fence panels and majority models of construction mesh!

IT IS ANOTHER CLEAR EXAMPLE OF UTMOST FEASIBILITY OF OUR PRODUCTS

Basic Operation Description

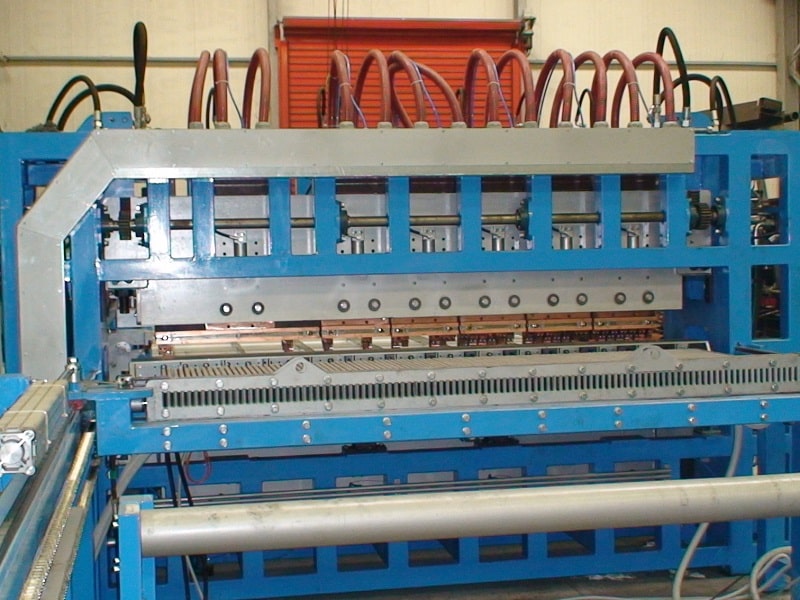

The machine takes pre-straightened and cut to length (6m) Bearing Bars are placed by the operator into a special feeding slots inside the feeding trolley. Trolley is advancing bars into the welding unit.

The pre-straightened & cut Cross Bar, wire feeder, releases one by one the cross wires (rectangular, twisted) and inserts them into the welding position

The loading of the cross bars into the hopper is done by the operator manually or by crane.

After loading of the bearing bars, the welding process is performed automatically in accordance with the programmed sequence

The advancing and line bars feeding process is very accurate due to the servo motors which are in duty to advance the flat bars thru the welding unit

The ready product will be discharged on a collection table; the removal can be done by crane.

Main features

- 2 CROSS Wires Feeding System

- Welding UNIT OPERATES pneumatically / hydraulically.

- PREASURRE of each welding spot separately programmable

- DIRECT (spot) WELDING system for complete control.

EXCLUSIVE features:

- Produces the WHOLE RANGE of grating models

- DOUBLE CROSS wire allows for ALL EXISTING types of 2D Fence Panels.

- Supreme Flexibility in the production regime

- Respectable speed of max. 50 strokes/min.

Featured Performance Options:

Type of wire and blades: be mild black or galvanized low carbon steel with max. Tensile Strength of 450 – 550 N/mm²

Twisted Wires diameter 4.0 mm – 6.0 mm, typically

Wires Step 20 min mm

Bearing Bar size: 3×30 – 10x80mm max.

Bearing Bar Step 20mm

Machine width: ~1000-2000 mm

Grating length: ~6m

Theoretical production speed 30- 50 cross wire /min depending on the blades size