ULTRA-HIGH SPEED, HIGH PRECISION WELDED MESH MACHINE IN SHEETS & ROLLS

TYPE UH BIWELSTATE-OF-THE-ART, completely automatic, wire mesh welding machine for the production of PANELS/SHEETS, or, ROLLS of Ultra High Precision (of 0.2mm).

This steel wire mesh welding machine is specially recommended for critical applications in various industry screening and precision metal lathing!

Basic Operation Description

Wire coils are mounted on dedicated pay-offs for Line wire feeding.

Dedicated tension and missing wire control device is helping keep wires nicely separated and easy to control.

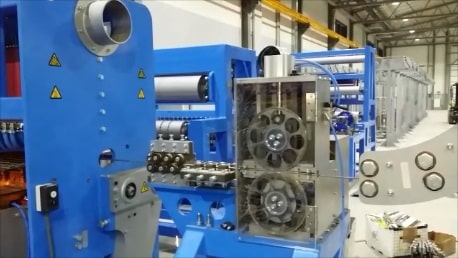

The cross wire is off-coiling from the stable/motorized pay-off station. Wire is pulled by the buffer feeding rollers, and goes through the pre-straighteners, buffer, servo-feeding rollers and final straighteners The needed length of wire is advanced into the welding station, cut at exact length and positioned for welding, by special devices.

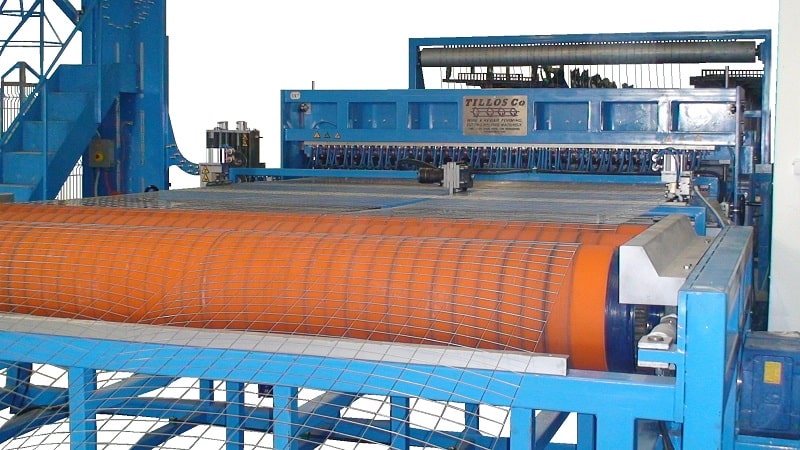

The advancing of the mesh is servo controlled pulling action.It can be achieved by SINGLE/DOUBLE CARRIAGE system, or, POLYURETHANE drums, depending on the products needed and the dimensions of the machine.

Dedicated cutter is severing the ready mesh at the programmed size.

Any type of stacking can be employed!In case of the production of coiled mesh in rolls, ready mesh is coiled by dedicated rolling device, at programmed length! Managing of the mesh and the evacuation of the roll can be completely automatic!

Main features

- Choice of Direct (spot) or, Bridge Welding, depending on application.

- Our Cross wire shooting system for absolute control of the geometry!

Exclusive Features:

- ULTRA-HIGH PRECISION ability, at maximum 0.2mm error!

- Unmatched GEOMETRICAL ALINEMENT eliminates the unnecessary overheads. Trimmed parts are up to 8 times smaller than the competition, 800% less scrap/day!

- WORLD’S EXCLUSIVE 4th generation, cross wire shooting/feeding system.

- RECORD-BREAKING SPEED at 200 strokes/minute.

- Specially adjusted direct/spot welding.

Featured Performance Options:

- Speed at ~ 200 strokes/minute!

- Width from 600 up to 3000mm

- Wire diameter from 0.8mm up to 3.0mm

- Cross wire pitch/distance – infinitely adjustable

- Line wire pitch/distance could be as small as 1/2 inch