High Capacity, Steel Reinforcement Mesh Sheets

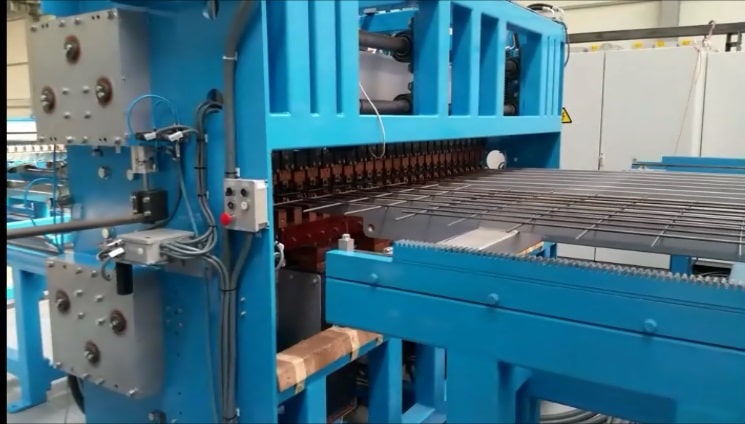

Welding line production off-coil-Type DOWELThis type of machine is fully automatic for the production of construction mesh in sheets.

Line and cross wires feeding is directly from spools, via pay-offs.

Specially designed cross wire up/down shooting system, there is no need for overturning.

Basic Operation Description

Wire coils/spools are mounted on dedicated pay-offs for Line wire feeding.

Motorized rollers are pulling the line wires, helping them uncoil smoothly! Horizontal straighteners are helping keep the wire nicely separated and easy to control though the dedicated buffer and tension/missing wire control. Wires are then advanced by the second set of Servo – Motorized rollers, through the vertical straighteners, into the welding machine!

The cross wire is off-coiling from the motorized pay-off station. Wire is pulled by the buffer feeding rollers, and goes through the pre-straighteners, buffer, servo-feeding rollers and straighteners.

Mesh is advanced and dedicated cutter is cutting it, at the programmed size.

Any type, from simple to fully automatic stacking is available!

The complete operation is automatic and easily programmable!

Main features

- DIRECT (spot) WELDING system for complete control.

- Our Cross wire shooting system guarantees flatness of each sheet!

Exclusive Features:

- Produces all types of Standard Steel Reinforcement Mesh Sheets

- Cross wire UP/DOWN SHOOTING system, no OVERTURNING needed!

- SECOND CROSS WIRE FEEDING system DIMINISHES downtime

- WORLD’S EXCLUSIVE 5th generation, cross wire shooting/feeding system

- RECORD-BREAKING speeds at over 150 strokes/min and ultimate precision.

- Automatic OVERHANG size adjustment

Featured Performance Options:

- Width from !2000mm to 3600mm

- Wire diameter from 5mm – 10mm

- Cross wire step – from 50mm – infinitely adjustable

- Line wire spacing 100, 150, 200mm, typically

- Works with Stainless Steel

- Easy to ADJUST to produce mesh in ROLLS

- SELECTION of Dedicated Cutter TYPES